What is called Resistance Thermometer?

A resistance thermometer is a device which uses the resistance of an electrical conductor in measuring the temperature of a source. It is a very accurate temperature sensing device widely used for high temperature measurement.

It is commonly known as Resistance Temperature Detector or RTD .

Working Principle of Resistance Thermometers

The resistance of a conductor varies with change in it’s temperature. The linear variations of electrical resistance or resistivity of conductors with rise in temperature is used by resistance thermometers for measurement of temperature of a source.

The governing relation of thermometric property is given by –

T = \left [ \left ( \frac { R_t - R_0 }{ R_{100} - R_0 } \right ) \times 100 \degree C \right ]

Where ( R ) is the electrical resistance of a conductor. It works on the principle of wheat stone bridge.

Materials used for RTD

The following are the required qualities of a material to be used as an element in the resistance thermometers.

- Resistivity of sensing material should be high so that, the minimum volume of conductor is needed for construction of thermometer.

- It should have linear or nearly linear relationship of change in resistance with the change in temperature.

- The material should have high thermal co-efficient of resistance. This means that, the change in resistance with change in temperature should be as high as possible.

- It must have high melting point so that, it should sustain at high temperatures.

Some materials, like carbon have non linear relationship of change in resistance with temperature. Semiconductors like germanium and silicon have negative thermal co-efficient. So, their resistance decrease with increase in temperature. Hence, these materials are not suited for wide application in resistance thermometers.

The change in resistance of most of metals is found direct proportional and linear to their change in temperature. Therefore, pure metals are extensively used as sensing elements in the construction of resistance thermometers.

- Gold and silver elements are not used in RTD because they have low resistivity.

- Tungsten has high resistivity and high temperature sustainability, but it is extremely brittle.

- The copper is cheap, has high resistivity and may be used for making RTD element. But it has disadvantage that, it has low linear relation between change in resistance and temperature. Also it has low temperature range. The maximum temperature of the copper is about 120 \degree C .

- The resistance thermometers sometime use nickel or its alloy as sensing element. The nickel wires are used for a limited temperature range, but they are also nonlinear.

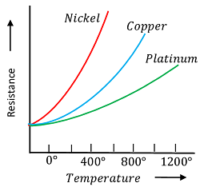

The resistance versus temperature curve for some metals is shown in figure. It is evident that, the curves are nearly linear for small temperature ranges. However, platinum has almost a linear curve and widely used in RTD .

Types of Resistance Thermometers

Resistance thermometers are of two types –

- Platinum resistance thermometer.

- Germanium resistance thermometer.

These are explained as follows –

Platinum Resistance Thermometer

A platinum resistance thermometer has an element made up of platinum wire in its bulb for sensing the temperature of a heat source. It is also called as PRT

- The resistance of platinum changes linearly with the change in temperature.

- The platinum thermometer is capable of measuring the temperature over a great range of 200 \degree C to 1200 \degree C .

Following properties of platinum makes it most suitable for wide application in RTD .

- Platinum is a ductile metal. It is non reactive. It can be drawn into fine wires easily to make a filament.

- It has high stability and it can sustain at very high temperatures. This makes it capable for measurement of very high temperatures.

- Platinum has high resistivity. It means higher thermal coefficient of resistance. A low change in temperature brings a considerable change in resistance.

- It has almost a linear relationship between variation of resistance and change in temperature.

This makes platinum most suitable for use in resistance thermometers.

Construction of Platinum Thermometer

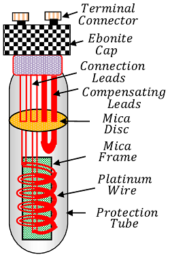

Construction of a platinum resistance thermometer is shown in figure. It consists of the following following –

- Resistance Element – It is a coil made of platinum wire used for sensing the temperature. Two wires are used for coil to reduce the inductive effect. The platinum wire is protected by stainless steel tube or by a glass coating on wire.

- Connection Leads – Two copper wires are used as connection leads. These leads extend from the platinum element for connecting the thermometer in the circuit of a wheatstone bridge. The lead wires are covered by the insulated tube to protect them from short circuit.

- Compensating Leads – Since, connection lead copper wires has some resistance, so to reduce the effect of their resistance, two similar copper wires are also inserted parallel to the connection leads at upper end of terminals. These are called the compensating leads.

- Mica Insulator – To give a shape to the element and for providing an insulation, platinum wire coil is wound around a mica strip. Mica disc is also used to hold the leads at position.

- Thermometer Bulb – The platinum sensing coil is enclosed inside a bulb which is made of glass or Pyrex. It is the part which is inserted into the heat source.

- Protection Tube – The whole thermometer unit is placed inside a protective tube for providing protection against damages. This is made up of stainless steel or copper steel or glass ceramic. The ceramic material is used as an insulator for high temperature range and fiber or glass is used for low temperature range.

- Ebonite Cap – The Ebonite cap is placed at the open end of the protection tube. It holds the entire thermometer unit including connection leads and compensating lead screws.

Working of Platinum Thermometer

For measurement of temperature of a source, the bulb holding the sensing element of the thermometer is placed near the heat source. The heat is uniformly distributed across the element. After thermal equilibrium of the bulb, the change in the resistance of the element is recorded which gives the measure of the temperature by simple calculations.

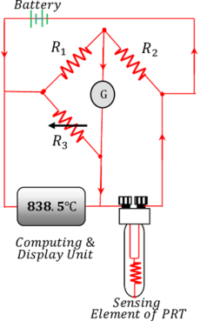

Resistance of platinum element increases linearly with rise in temperature. Thermometer is connected in place of fourth resistance in a wheat-stone bridge or potentiometer circuit. The final resistance R_T of the element is measured by passing an alternating or direct current through the bridge circuit. Adjustable resistance R_3 is so adjusted such that deflection in Galvanometer is nearly zero. When the bridge is so balanced, the reading of voltage across variable resistance R_3 is converted into the temperature scale with the help of the calibration equation by the computing and display unit.

Connection procedure of the platinum element in wheat-stone bridge circuit is shown in figure. The condition of balanced bridge forms the basic component of temperature measuring system.

At balanced condition, the deflection of the Galvanometer is zero and then following relation exists –

\left ( \frac {R_1}{R_2} \right ) = \left ( \frac {R_3}{R_T} \right )

In normal practice, the sensing element is far away from the bridge. So, connection leads have a resistance that can’t be neglected. If \left ( R_{c1} \ \& \ R_{c2} \right ) are the resistances of the connection leads, then –

\left ( \frac {R_1}{R_2} \right ) = \left ( \frac {R_3 + R_{c1} + R_{c2}}{R_T} \right )

Advantages of Platinum Thermometer

Platinum resistance thermometer has following advantages –

- Temperature measurement with platinum resistance thermometer is easier as compared to the gas thermometer.

- The thermometer gives precise reading of temperature over a wide range from 200 \degree C to 1200 \degree C .

- This thermometer is very sensitive.

- The platinum material has same resistance stable at a given temperature.

- The temperature resistance element can be easily installed and replaced.

- It has performance stability over longer periods of use.

Disadvantages of Platinum Thermometer

The following are the disadvantages of platinum thermal resistance –

- The thermometer gives slow response.

- The melting point of the thermometer is 1800 \degree C . But, when the platinum thermometer is used to measure the temperature higher than 1200 \degree C , platinum start evaporating.

- A platinum thermometer is not suitable for dynamic temperature measurements.

- It has high cost due to need of bridge and power source.